Essential Tips for Polishing and Buffing Pad Care

Share

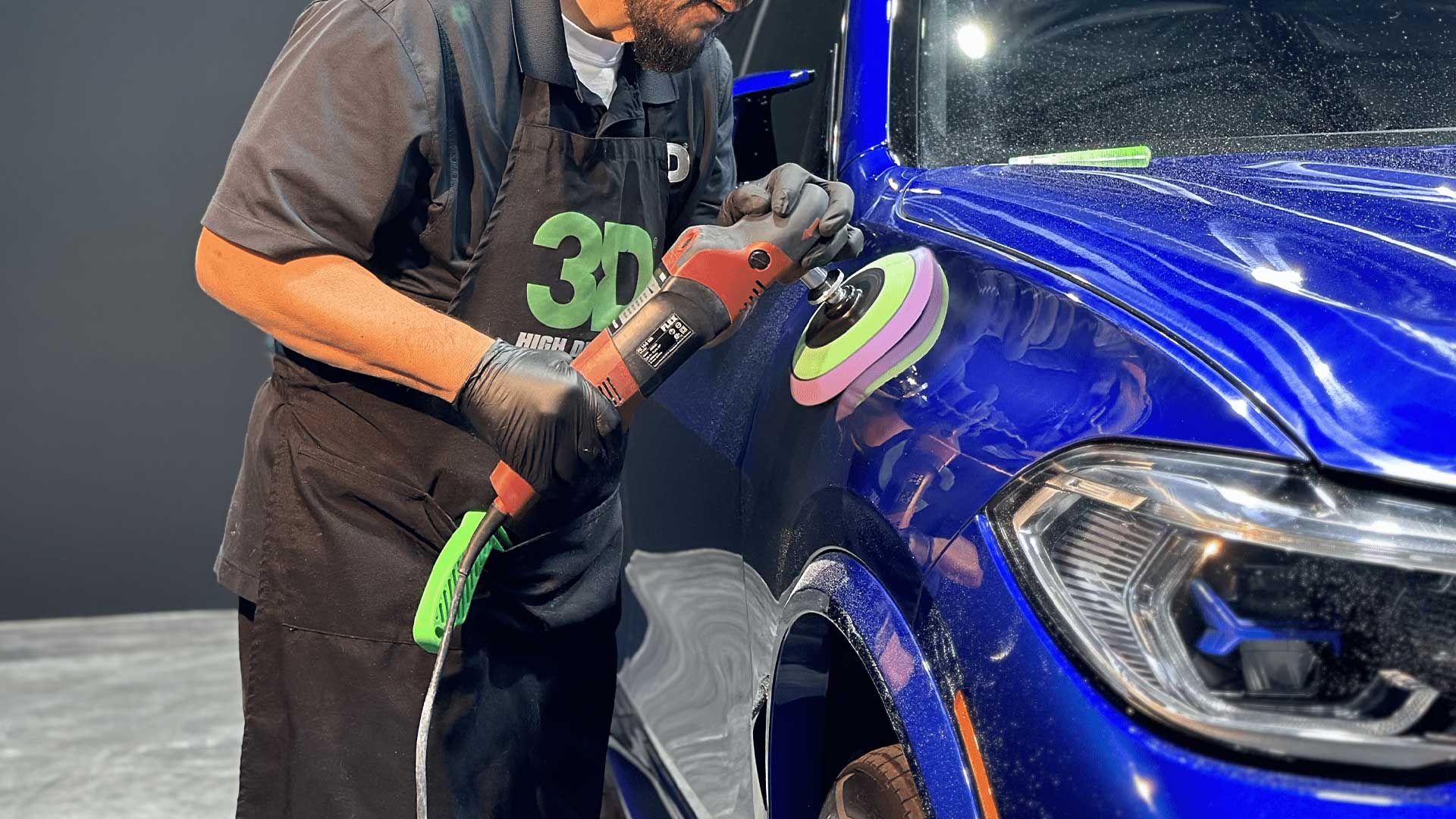

Proper maintenance of buffing, polishing pads and applicators is a critical aspect of car detailing that ensures a flawless finish and extends the life of these essential tools. Clean buffing pads are vital for achieving the best results, as they prevent the build-up of residues that can mar the vehicle's surface. Whether you're dealing with wool, foam, or microfiber pads, each type has unique properties and maintenance needs.

Wool pads are known for their cutting power, making them ideal for removing scratches and oxidation. However, they can also generate more heat and require careful handling to avoid damage to the paint. Foam pads come in various levels of firmness and are used for everything from heavy cutting to fine polishing. They tend to produce less heat and offer a more controlled buffing experience. Microfiber pads, on the other hand, provide a balance between cutting ability and finishing quality, making them versatile for various detailing tasks. To maintain these pads, it's essential to clean them regularly.

It's crucial to wash polishing pads correctly to avoid damaging them and to ensure they continue to perform at their best. Proper drying techniques are also important to prevent the pads from losing their shape or backing.

In summary, the maintenance of buffing, polishing pads and applicators is not just about keeping them clean; it's about preserving their functionality and ensuring the highest quality finish on your car detailing projects. Regular cleaning and proper care will help you avoid common issues such as micro-marring and product build-up, ultimately saving time and money while delivering superior results.

Understanding Wool and Foam Pads

In the realm of car detailing, wool and foam pads play pivotal roles in paint correction and scratch removal, each bringing unique characteristics and benefits to the process. Understanding these differences is crucial for selecting the right pad for your detailing project.

Wool Pads

Wool pads are renowned for their aggressive cutting ability, making them an excellent choice for quickly removing scratches, oxidation, and other paint imperfections. These pads are made from natural wool fibers, which are inherently abrasive, allowing them to level the paint surface efficiently. One of the key advantages of wool pads is their excellent heat dissipation. Unlike some synthetic materials, wool does not trap heat as easily, which helps keep the surface cooler during the polishing process and reduces the risk of burning the paint. However, their aggressive nature means they must be used with care to avoid introducing new swirls or holograms into the paint.

Foam Pads

Foam pads, on the other hand, offer a more controlled and versatile approach to detailing. They come in a variety of densities and structures, each designed for specific stages of the detailing process: cutting, polishing, and finishing.

- Cutting pads are firmer and used to remove deeper scratches and defects.

- Polishing pads have a medium density and are used to refine the surface after cutting, preparing it for the final finish.

- Finishing pads are soft and designed for applying waxes, sealants, or for final polishing to achieve a high-gloss finish.

Foam pads are known for their durability and versatility, capable of being used with different types of polishers, including rotary and dual-action machines. Their structure allows for even distribution of polishing compounds and provides a consistent finish across the surface. Additionally, foam pads are less likely to generate excessive heat compared to wool, making them safer for novice detailers to use.

In summary, both wool and foam pads are indispensable tools in the car detailing arsenal, each suited for different stages of the paint correction process. Wool pads offer aggressive cutting power and efficient heat dissipation for tackling severe defects, while foam pads provide a range of options from heavy cutting to fine finishing, offering versatility and safety for various detailing tasks.

Why Proper Pad Maintenance Matters

The maintenance of buffing and polishing pads is not just a matter of cleanliness; it's a crucial practice that directly impacts the quality of your work, the lifespan of your pads, and the safety of the vehicles you service. Proper pad maintenance is essential for several reasons:

Prolonging Pad Lifespan

Regular cleaning and proper storage of polishing pads can significantly extend their useful life. As pads accumulate product, they can become saturated and lose their effectiveness. This saturation not only diminishes the pad's cutting or polishing ability but can also lead to premature breakdown of the pad's material. By keeping pads clean and properly maintained, you ensure that each pad can serve its purpose for as long as possible, handling multiple vehicles over time and providing consistent results.

Avoiding Contamination Risks

Using a dirty pad can introduce contaminants back onto the vehicle's surface, risking micro-marring and other paint defects. Cross-contamination between pads, especially when switching between different compounds or stages of detailing, can also occur if pads are not properly cleaned between uses. This can adulterate the products being used, diluting their effectiveness and potentially damaging the vehicle's finish. Proper pad maintenance helps avoid these risks, ensuring that each pad is clean and free of contaminants before it touches the vehicle.

Ensuring Consistent Performance

A clean buffing pad is crucial for achieving the desired finish on a vehicle's surface. When pads are clogged with spent product and removed paint, they can't distribute fresh product evenly, leading to inconsistent results and potentially more work to correct these inconsistencies. Clean pads ensure that each pass with the polisher is as effective as the first, maintaining the pad's cutting or polishing ability throughout the detailing process.

How To: Cleaning and Maintenance of Wool Pads

Cleaning wool buffing and polishing pads is essential to maintain their effectiveness and prolong their lifespan. Here is a simple step-by-step guide on how to properly wash and clean wool pads:

- Preparation: Before starting the cleaning process, ensure you have the necessary tools such as a spur or compressed air for removing excess residue without wetting the pad.

- Inspect the Pad: Check the wool pad for any large debris or buildup that can be easily removed by hand or with a spur tool.

- Use Spur or Compressed Air: If available, use a spur tool to gently remove dried polish residue from the wool fibers. Alternatively, you can use compressed air to blow out any loose particles.

Remember, never wash 3D wool pads as they are natural and still attached to the hide, which can cause them to lose their shape when wet. Following these steps will help keep your wool buffing and polishing pads in optimal condition for future use.

How To: Cleaning and Maintenance of Foam Pads

To effectively clean foam buffing and polishing pads, follow these simple steps:

- Inspect and Remove Debris: Check the foam pad for any visible debris or residue that can be easily removed by hand or with a nylon brush.

- Use Nylon Brush or Compressed Air: Lightly press a nylon brush against the pad to remove excess residue. Alternatively, use compressed air to blow out any remaining particles.

- Spot Clean: For localized stains or dirt, spot clean the affected areas with a mild cleaner suitable for foam pads. Gently dab the cleaner on the stain and rinse with water.

- Machine Wash or Hand Wash: Foam pads can be cleaned in a washing machine on a gentle cycle or by hand using warm water and a suitable cleaner. Allow the pads to soak in a bucket of water mixed with a cleaning solution to break down polish residue.

- Rinse Thoroughly: After washing, rinse the foam pads thoroughly with clean water until all cleaning solution is removed.

- Air Dry Only: To dry the foam pads, lay them flat on a clean towel in a well-ventilated area away from direct heat sources. Ensure they are completely dry before using them again.

- Maintain Shape and Texture: Once dry, ensure the foam pads are fluffed and reshaped by gently brushing them with your hand or a soft-bristled brush.

- Storage: Store the clean and dry foam buffing and polishing pads in a cool, dry place to prevent mold or mildew growth.

Remember never to dry foam pads with heat as it can damage their texture and effectiveness. By following these steps, you can keep your foam buffing and polishing pads in optimal condition for future use.

Best Practices for Both Types of Pads

Maintaining both wool and foam pads requires a diligent approach to inspection, handling, and replacement. By adhering to best practices, you can ensure that your pads remain in optimal condition for as long as possible, providing consistent results and protecting the vehicle's finish.

By implementing a regular inspection routine, proper handling techniques and rotation and replacement schedules, you can ensure you are getting the most out of your wool or for pads and applicators.

Replacement of pads should be done using your best judgment during the inspection process. While the tips above can help extend the life of your pads, it's important to recognize that every type of pad, material, and manufacturer differs in lifespan. When a pad shows signs of excessive wear or no longer performs as expected, it's time to replace it. Always err on the side of caution; a pad that is past its prime can do more harm than good to a vehicle's finish.

Looking for the Best Pads? 3D Has You Covered

When it comes to achieving a perfect finish on your vehicle, the quality of your buffing and polishing pads is just as important as your technique. As we've discussed, regular inspection, proper handling, and timely rotation and replacement are key to maintaining pad performance and longevity. Clean buffing pads are essential for consistent results and avoiding contamination risks, which is why proper pad maintenance cannot be overlooked.

3D Car Care offers a range of high-quality wool and foam pads designed to meet the needs of both professional detailers and car enthusiasts. Our wool pads, sourced from the finest lambswool in Australia, feature a proprietary treatment process that ensures fast cutting, high efficiency, and minimal linting. The uniform pile and non-shedding nature of these pads result in a smoother finish with fewer holograms.

Our foam pads come in sizes ranging from 3" to 8" and include a unique spider-cut design that enhances their effectiveness. This design allows for increased surface area contact and better heat dissipation, ensuring a cooler buffing experience and longer pad life. The versatility of these pads is unmatched, as they can be used for light cutting, medium polishing, or fine finishing, depending on the product used.

To help keep these pads clean and functioning at their best, we also offer a pad cleaning spur. This tool is designed to quickly and safely clean wool buffing pads, removing compound and polish residue without damaging the fibers. With the 3D pad cleaning spur, you can maintain your pads in between uses, ensuring they are always ready for the next job.

By choosing 3D's range of buffing pads and backing plates, you're not only investing in top-notch products but also in the longevity and effectiveness of your detailing tools. Remember, clean and well-maintained pads are the secret to a flawless finish and a testament to your professionalism in car care.