When it comes to paint correction, detailers often face a familiar dilemma. Do you go all-in with a multi-step compound-and-polish process, or is there a faster way to achieve serious gloss and real correction?

Enter 3D SPEED, a professional-grade all-in-one polish that removes light scratches and swirls, restores deep gloss, and seals the surface with lasting protection in a single, time-saving step.

Designed as a true one-step solution, 3D SPEED combines defect removal and durable protection in a single pass. It is built for enthusiasts who want professional-level results without complexity, and for professionals who need efficiency without sacrificing finish quality.

Let’s break down exactly where SPEED fits in your detailing workflow, what it corrects best, how to dial in your pad and machine setup, and when it makes more sense than a multi-stage correction.

3D SPEED Explained: One-Step Paint Correction Without the Guesswork

What Is 3D SPEED?

3D Car Care SPEED is an all-in-one polish that blends the corrective bite of a compound, the refining touch of a polish, and the protection of a wax into a single bottle built for real-world enthusiasts and working pros alike. It is designed to cut light scratches and swirls, restore depth and gloss, and lay down durable protection in one streamlined step.

SPEED works on virtually any painted surface, gelcoat, and many plastics, and even handles light water spots and road film on glass. The zero-dusting formula keeps the job clean, whether you are working in your home garage or a professional shop.

It can be applied by hand for the weekend detailer or with a dual-action polisher for faster, more consistent results. While a rotary can be used carefully, a DA polisher is where SPEED truly shines. With up to six months of durability on a daily driver, it delivers a rich, protected finish without turning a simple detail into a full weekend project.

In short, 3D Car Care SPEED is a time-saving, gloss-building, paint-correcting solution that makes achieving a deep, protected shine refreshingly straightforward.

SPEED works on virtually any painted surface, gelcoat, and many plastics, and even handles light water spots and road film on glass. The zero-dusting formula keeps the job clean, whether you are working in your home garage or a professional shop.

It can be applied by hand for the weekend detailer or with a dual-action polisher for faster, more consistent results. While a rotary can be used carefully, a DA polisher is where SPEED truly shines. With up to six months of durability on a daily driver, it delivers a rich, protected finish without turning a simple detail into a full weekend project.

In short, 3D Car Care SPEED is a time-saving, gloss-building, paint-correcting solution that makes achieving a deep, protected shine refreshingly straightforward.

Where 3D SPEED Fits in a Detailing Workflow

Every strong finish starts with proper prep. SPEED is not a shortcut around preparation. It is the reward for doing it right.

3D SPEED works best after:

That is where it earns its reputation.

3D SPEED works best after:

- A thorough wash using a quality shampoo

- Chemical decontamination with an iron remover when needed

- Clay bar or clay towel treatment to remove bonded contaminants

- A proper paint inspection under good lighting

That is where it earns its reputation.

What Defects Does 3D SPEED Handle Best?

3D SPEED shines when addressing:

That balance makes it ideal for:

- Light to moderate swirl marks

- Fine surface scratches

- Water spots with light etching

- Oxidation

- Haze

- Dull, lifeless paint

That balance makes it ideal for:

- Softer paint systems where heavy compounding is unnecessary

- Well-maintained vehicles that simply need enhancement

- Quick improvement jobs where efficiency matters

- Harder clears when paired with a more aggressive pad

When to Choose 3D SPEED Over Multi-Stage Correction

Choose SPEED when:

- Time efficiency matters

- The paint has light to moderate defects

- The goal is strong improvement rather than perfection

- You are maintaining a vehicle and want added gloss and protection

- You want correction and protection in one streamlined step

- Heavy scratches require leveling

- Severe oxidation needs aggressive compounding

- You are pursuing near-perfect show-car results

- Wet sanding marks must be removed

Buffing Pad Pairings: Dialing In Your Cut and Finish

One of SPEED’s biggest strengths is versatility, and the pad you choose becomes the tuning knob for how much correction you want.

For a full breakdown of pad types and how they interact with SPEED, explore our complete guide: A Guide to Buffing Pads and 3D SPEED

For a full breakdown of pad types and how they interact with SPEED, explore our complete guide: A Guide to Buffing Pads and 3D SPEED

Buffing Pad General Recommendations

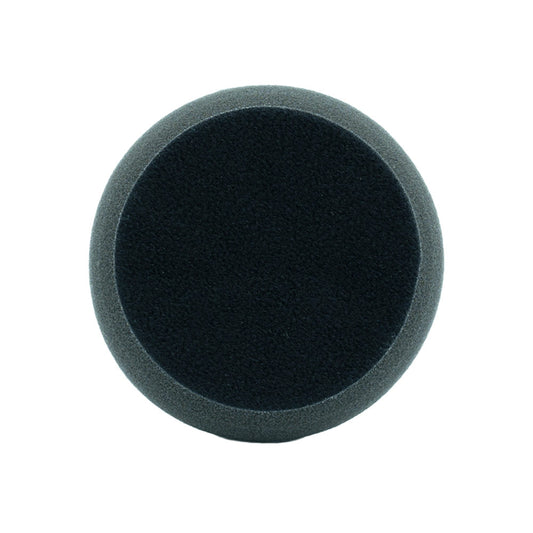

Light Cutting Foam Pad

Delivers increased correction while still finishing well. Ideal for moderate swirls or slightly neglected paint that needs real improvement without stepping into a full compound stage.

Polishing Foam Pad

The sweet spot for most vehicles. Balanced correction and strong gloss enhancement. Perfect for maintenance details and one-step enhancements.

Finishing Pad

Minimal correction with maximum gloss. Excellent for well-kept vehicles that need clarity and protection rather than defect removal.

Microfiber Pads for Advanced Users

Significantly increase correction capability, especially on harder clear coats. Follow up with lighter pressure or a softer pad if additional refinement is needed.

Always perform a test spot first. Let the paint tell you what it wants. Every surface responds a little differently, and dialing it in early saves time across the entire vehicle.

Always perform a test spot first. Let the paint tell you what it wants. Every surface responds a little differently, and dialing it in early saves time across the entire vehicle.

3" White Wool Cutting Pad

3" White Wool Cutting Pad

Regular price

$19.99

Sale price

$19.99

Regular price

Unit price

per

3.5" Black Spider-Cut Foam Finishing Pad (2 Pack)

3.5" Black Spider-Cut Foam Finishing Pad (2 Pack)

Regular price

$24.99

Sale price

$24.99

Regular price

Unit price

per

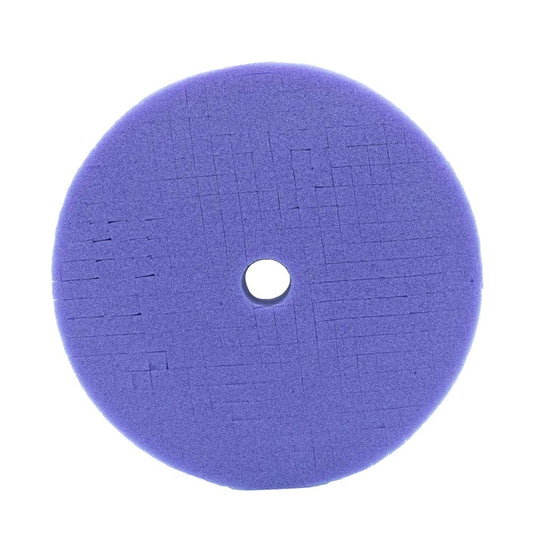

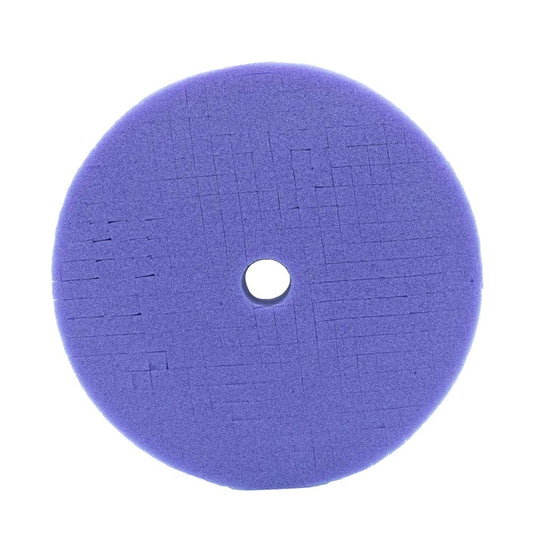

3.5" Dark Purple Spider-Cut Foam Cutting Pad (2 Pack)

3.5" Dark Purple Spider-Cut Foam Cutting Pad (2 Pack)

Regular price

$24.99

Sale price

$24.99

Regular price

Unit price

per

3.5" Light Purple Spider-Cut Foam Polishing Pad (2 Pack)

3.5" Light Purple Spider-Cut Foam Polishing Pad (2 Pack)

Regular price

$24.99

Sale price

$24.99

Regular price

Unit price

per

3.5" White Spider-Cut Foam Cutting Pad (2 Pack)

3.5" White Spider-Cut Foam Cutting Pad (2 Pack)

Regular price

$24.99

Sale price

$24.99

Regular price

Unit price

per

5" White Wool Cutting Pad

5" White Wool Cutting Pad

Regular price

$29.99

Sale price

$29.99

Regular price

Unit price

per

5.5" Black Foam Finishing Pad

5.5" Black Foam Finishing Pad

Regular price

$29.99

Sale price

$29.99

Regular price

Unit price

per

5.5" Dark Purple Foam Cutting Pad

5.5" Dark Purple Foam Cutting Pad

Regular price

$29.99

Sale price

$29.99

Regular price

Unit price

per

5.5" Light Purple Foam Polishing Pad

5.5" Light Purple Foam Polishing Pad

Regular price

$29.99

Sale price

$29.99

Regular price

Unit price

per

5.5" White Spider-Cut Foam Cutting Pad

5.5" White Spider-Cut Foam Cutting Pad

Regular price

$29.99

Sale price

$29.99

Regular price

Unit price

per

6" White Wool Cutting Pad

6" White Wool Cutting Pad

Regular price

$34.99

Sale price

$34.99

Regular price

Unit price

per

6.5" Black Spider-Cut Foam Finishing Pad

6.5" Black Spider-Cut Foam Finishing Pad

Regular price

$34.99

Sale price

$34.99

Regular price

Unit price

per

6.5" Dark Purple Spider-Cut Foam Cutting Pad

6.5" Dark Purple Spider-Cut Foam Cutting Pad

Regular price

$34.99

Sale price

$34.99

Regular price

Unit price

per

6.5" Light Purple Spider-Cut Foam Polishing Pad

6.5" Light Purple Spider-Cut Foam Polishing Pad

Regular price

$34.99

Sale price

$34.99

Regular price

Unit price

per

6.5" White Spider-Cut Foam Cutting Pad

6.5" White Spider-Cut Foam Cutting Pad

Regular price

$34.99

Sale price

$34.99

Regular price

Unit price

per

7.5" Black Spider-Cut Foam Finishing Pad

7.5" Black Spider-Cut Foam Finishing Pad

Regular price

$34.99

Sale price

$34.99

Regular price

$39.99

Unit price

per

7.5" White Spider-Cut Foam Cutting Pad

7.5" White Spider-Cut Foam Cutting Pad

Regular price

$39.99

Sale price

$39.99

Regular price

Unit price

per

8" White Wool Cutting Pad

8" White Wool Cutting Pad

Regular price

$42.99

Sale price

$42.99

Regular price

Unit price

per

8" Yellow X-Cut Lambswool Pad

8" Yellow X-Cut Lambswool Pad

Regular price

$42.99

Sale price

$42.99

Regular price

Unit price

per

Glass Polishing Pad (3 Pack)

Glass Polishing Pad (3 Pack)

Regular price

$12.99

Sale price

$12.99

Regular price

Unit price

per

Machine Speed and Technique Recommendations

One of SPEED’s biggest strengths is versatility, and the pad you choose becomes the tuning knob for how much correction you want.Technique separates average results from standout finishes.

3D SPEED performs exceptionally well with dual-action polishers and can be used with rotary machines when appropriately handled.

3D SPEED performs exceptionally well with dual-action polishers and can be used with rotary machines when appropriately handled.

Dual-Action Polisher

- Speed setting 4 to 5 for correction

- Slow, controlled arm movement

- Moderate pressure for initial passes

- Lighten pressure on final passes to refine

- Work in approximately 2-foot by 2-foot sections

Rotary Polisher

- RPM range between 1000 and 1400

- Start lower, increase slightly for correction

- Reduce pressure and RPM to finish down

The Smart One-Step Solution

For car enthusiasts who care about their paint and value convenience, 3D Waterless Car Wash delivers exactly what it promises. Fast, effective, and safe, it’s a solid addition to any detailing shelf.3D SPEED is not about cutting corners. It is about working smarter and understanding what most vehicles actually need.

For the majority of real-world detailing situations, it delivers meaningful correction, impressive gloss, durable protection, and genuine time savings. That combination is why it continues to earn a place on professional carts and enthusiast shelves alike.

Pair it with the right pad, refine your technique, and let the results speak for themselves.

Learn more here: A Guide to Buffing Pads and 3D SPEED

For the majority of real-world detailing situations, it delivers meaningful correction, impressive gloss, durable protection, and genuine time savings. That combination is why it continues to earn a place on professional carts and enthusiast shelves alike.

Pair it with the right pad, refine your technique, and let the results speak for themselves.

Learn more here: A Guide to Buffing Pads and 3D SPEED