How to Ceramic Coat Wheels

Share

Everybody loves to clean caked-on brake dust and road grime from their wheels, right? No? We thought so.

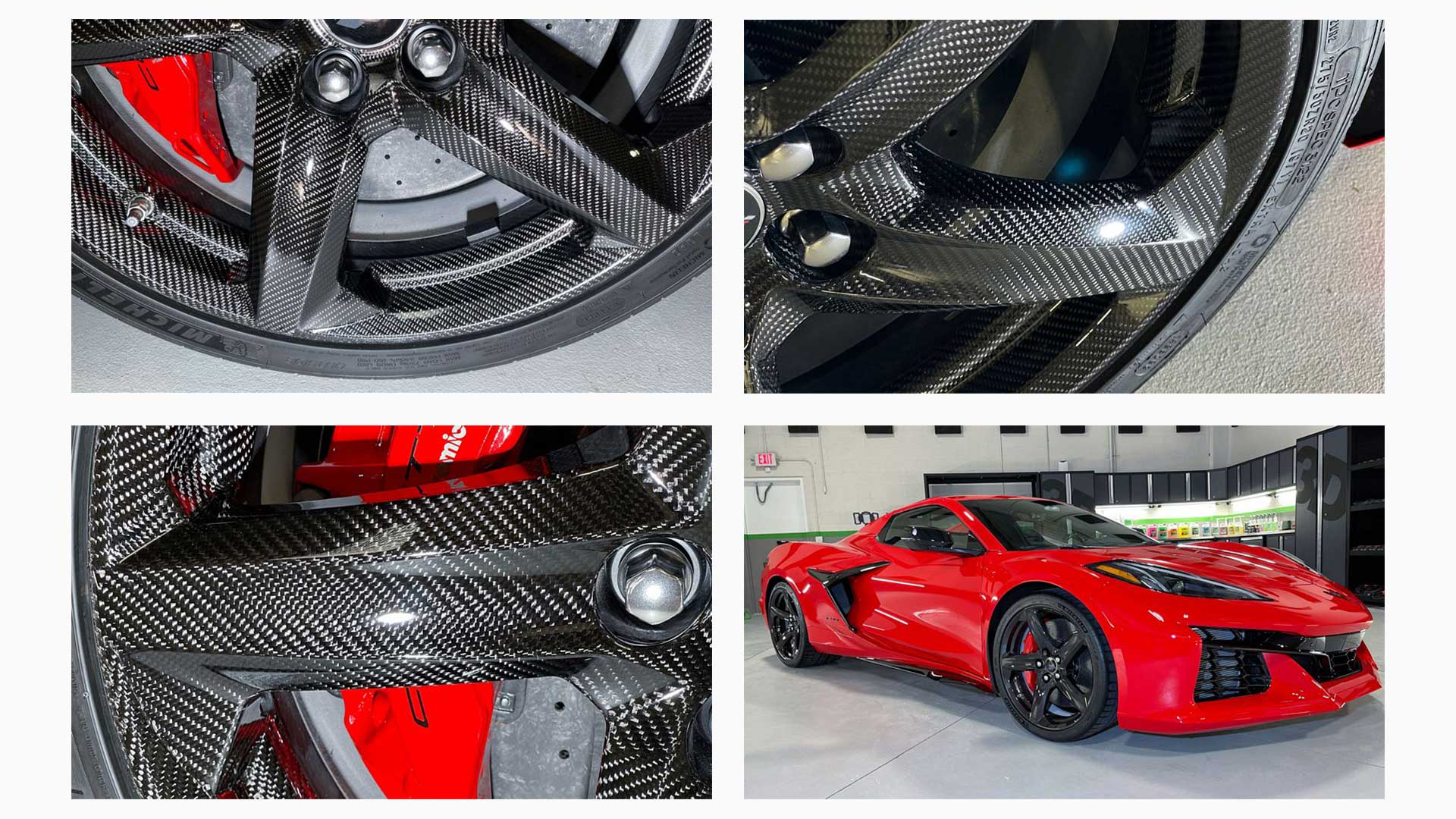

Ceramic coating has long been a popular and effective way to protect your vehicle. However, it has become an increasingly popular technique to protect your wheels as well. Ceramic coated wheels do a great job of keeping dirt, brake dust, and other contaminants to a minimum, while also making them easier to clean and maintain.

Ceramic coating wheels may seem like a daunting task, but with the proper tools, techniques, and some patience, you can achieve professional results in the comfort of your driveway or garage.

Whether your wheels are chrome, forged, flow forged, carbon fiber, or even OEM, ceramic coatings provide long lasting protection and gloss. There’s no better way to protect your investment than to ceramic coat your wheels.

Is Ceramic Coating Wheels Worth It?

Before we jump into how to ceramic coat your wheels, let’s take a second to understand why ceramic coating your wheels is beneficial:

Protection: Ceramic coatings create a strong, durable barrier between your wheels and the elements, helping to prevent damage from UV rays, road salt, brake dust, and other environmental factors.

Aesthetics: A ceramic-coated wheel will have a deep, glossy finish that is otherwise unachievable using traditional waxes or sealants, giving your car showroom shine.

Easy Maintenance: Ceramic coatings make your wheels easier to clean, as dirt and grime are less likely to adhere to the smooth, hydrophobic surface.

Longevity: When properly applied and maintained, a ceramic coating can last for several years, providing long-term protection for your wheels.

Now that you understand the benefits of ceramic coating your wheels, let’s dive into the ceramic coating process.

How to Ceramic Coat Wheels: Preparation

Before you begin the ceramic coating process, it's essential to properly prepare your wheels. This preparation ensures that the coating adheres correctly and provides the best protection for your wheels.

*Note: It’s recommended to completely remove the wheel from the vehicle in order to get the deepest clean possible, however the preparation process can be done with the wheel still mounted to the vehicle.

Follow these steps to get your wheels ready for ceramic coating:

Thoroughly clean your wheels: Start by washing your wheels with a dedicated wheel cleaner and a brush. This step removes any dirt, brake dust, or other contaminants that may be on the surface. Be sure to clean the face of the wheels, as well as the barrels if possible.

Decontaminate the surface: To further ensure a clean surface, use a decon product, like 3D GLW Iron Remover, to remove any lingering contaminants. Make sure to follow the directions closely for optimal results.

Polish the wheels (optional): If your wheels have any minor imperfections, such as light scratches or swirl marks, you may want to consider polishing them before applying the ceramic coating. Use a suitable wheel polish and a polishing pad to gently buff out these imperfections. This can be done either by hand, or with a machine.

Re-wash your wheels: Using a pH balanced car wash soap, thoroughly re-clean your wheels. This process will help remove any leftover contaminants and chemicals from the wheel’s surface, helping the ceramic coating bond. Be sure to fully wipe down and dry the wheels with a fresh microfiber towel.

How to Ceramic Coat Wheels: Coating

Now that your wheels have been properly prepped for ceramic coating, it’s time to apply the coating itself. Grab your 3D Graphene Infused Ceramic Coating and follow these steps to achieve a professional-looking finish and long-lasting protection for your wheels:

Shake the bottle: Before you start, give the bottle of ceramic coating a good shake to ensure that the product is thoroughly mixed.

Apply a few drops of the ceramic coating to an applicator pad: Using the included applicator pad in our kit, apply a few drops of the coating to the pad. You don’t need much, so use a small amount of product. Start with a conservative amount and add more if needed.

Work the ceramic coating into the wheel’s surface: Working on one wheel at a time, work the coating into the surface using small, circular motions. Ensure you’re covering the entire wheel, including the spokes, face, and barrel.

Allow the ceramic coating to dwell: After applying the ceramic coating to a wheel, allow it to dwell for at least 5 minutes. This will start the initial bonding process.

Buff off the excess: Once the applied coating has had decent dwell time, use a clean, dry microfiber towel to buff off the excess, ensuring an even and smooth surface.

Repeat the process for each wheel: Continue applying the ceramic coating, allowing it to dwell, and then buffing off the excess for each wheel on your vehicle. Be sure to follow the manufacturer's instructions for the specific product you are using, as curing times and application methods may vary.

Allow the ceramic coating to fully cure: After you have coated all of your wheels, allow the ceramic coating to fully cure for the recommended time, which is typically 24 to 48 hours. During this time, avoid getting your wheels wet or exposing them to extreme temperatures.

*Note: In order for the ceramic coating to fully form a strong bond and provide adequate protection, it is highly recommended to not drive the vehicle during the curing process.

How to Clean & Maintain Ceramic Coated Wheels

Once your wheels are ceramic coated and the curing process is complete, it’s important to clean and maintain them properly to promote longevity and continued protection.

When it’s time to clean your wheels again, be sure to use a pH neutral car wash soap, which is safe on ceramic coated surfaces. This type of cleaner will effectively remove dirt and brake dust without negatively impacting the coating. That said, avoid using harsh chemicals and abrasive tools. This includes iron removers, as it can eat away at the coating. It’s best to stick to a high-quality microfiber wash mitt when cleaning your coated wheels. As you normally would, thoroughly dry the wheels with a clean microfiber towel to prevent water spots and build-up. Lastly, one of our favorite ways to maintain coated surfaces is to use 3D GLW SiO2 Ceramic Detailer. This spray can be applied after each wash to enhance the gloss and protection of your wheels, while helping maintain the hydrophobic and self-cleaning properties of the coating.

What Not to Do

- Never use an iron remover, degreaser, or any other harsh chemicals on ceramic coated wheels. These types of cleaners will eat into ceramic coatings very quickly. As mentioned above, stick with pH neutral soaps and microfiber wash mitts.

- Never apply a ceramic coating to the threading on the hub face, lug nuts, or lug bolts. Because of its slippery properties, this can and will be a safety concern, so avoid these areas at all costs.

How Long Do Ceramic Coated Wheels Last?

The lifespan of ceramic coated wheels can vary depending on various factors, including the type of coating, the quality of application, and how well they are maintained. While there is no definitive answer, here are some general considerations:

Lifespan Range: Ceramic coated wheels can last anywhere from 2 to 5 years, with some exceptional cases reaching up to a decade. However, most coatings will fall within the 2 to 5-year range.

Proper Maintenance: To ensure the longevity of your ceramic coated wheels, it is essential to follow the recommended maintenance guidelines outlined above. This includes regular cleaning, avoiding harsh chemicals and abrasive tools, and applying a ceramic coating maintenance spray.

Real-World Situations: In real-world situations, the lifespan of ceramic coated wheels may be influenced by factors such as driving conditions, storage conditions, and exposure to elements. For example, a vehicle driven year-round in all four seasons may experience a slightly shorter lifespan.

Considerations for Reapplication: Over time, even the most durable ceramic coatings will begin to deteriorate, at which point it is best to strip the coat entirely and reapply a fresh layer. This reapplication process can help maintain the effectiveness of the coating and provide continued protection for your wheels.

While ceramic coated wheels can provide long-lasting protection and a beautiful finish for your vehicle’s wheels, it is important to understand that the lifespan of the coating may vary and is influenced by several factors. Proper maintenance and regular inspections can help you determine when it is time to reapply the ceramic coating for optimal performance.

The Best Ceramic Coatings for Wheels

When it comes to protecting your wheels with a high-quality ceramic coating, 3D Ceramic Coating Plus Graphene Infused is the industry leader. Our advanced technology offers superior oleophobic and hydrophobic properties, providing longer-lasting protection, shine, and beading ability for your wheels. Here's why this product stands out:

- Graphene Infused: 3D Ceramic Coating Plus is infused with graphene, making it the most durable and resistant ceramic coating from 3D Products yet. Graphene is a highly versatile material known for its exceptional strength and conductivity, making it an excellent addition to a ceramic coating formula.

- Long-Lasting Protection: Our ceramic coating offers lasting protection against dirt, dust, pollen, and grime, helping your wheels stay cleaner for longer. Its advanced formula creates a tough protective layer that can withstand the harsh environments wheels often face.

- Easy Application: Applying 3D Ceramic Coating Plus to your wheels is a straightforward process. You can follow the tips and techniques shared in this article. Proper preparation, patience, and following the instructions will help you achieve a quality coating ready to protect your wheels for months or even years to come.

To further enhance the longevity and performance of your ceramic coated wheels, consider using GLW Series Ceramic Detailer. This spray-on, wipe-off ceramic coating booster forms a strong bond to hard, smooth, clean surfaces, providing additional protection and shine for your wheels.